Leonard Bailey’s eponymous plane design was so good that bar a few minor tweaks by J A Traut in the early 1900s[1] it has remained pretty much unaltered since he invented it over 140 years ago. Needless to say this did not prevent various plane manufacturers, all of whom were producing basically identical products, to look for new gizmos that might distinguish their offerings from the competition. The next two articles discuss a couple of the more successful ideas: the Record “Stay-Set” cap iron and the two-part lever cap invented by Millers Falls.

Stay-Set cap irons

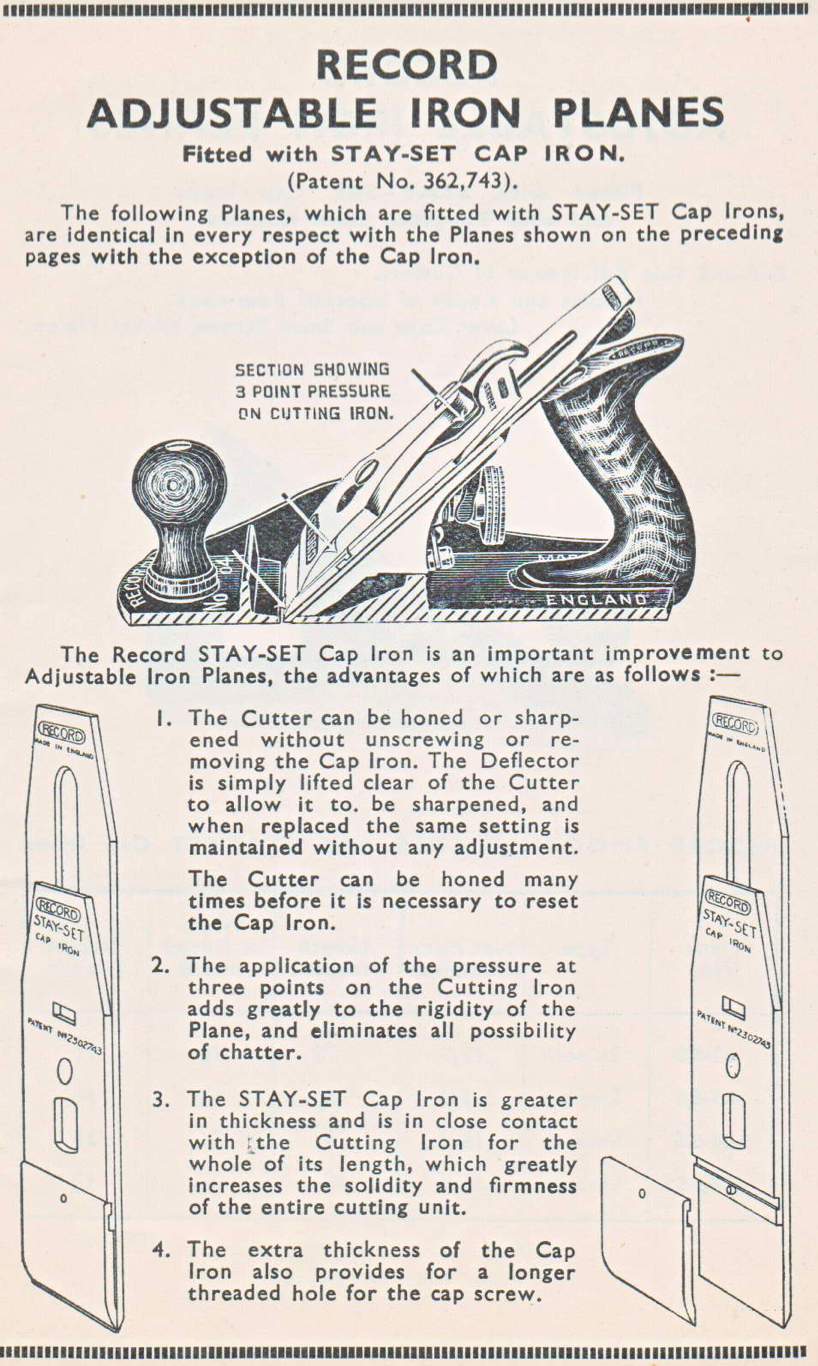

Record introduced the stay-set in 1931 at the same time they launched their range of bench planes. Record took the precaution of patenting the idea first, and the patent claims that:

- The plane can be sharpened without the need to adjust the position of the cap iron (this is the source of the brand-name, stay-set). Of course, since each sharpening removes a little metal, at some point you have to move the cap iron position back a little, but you get the idea.

- The clamping pressure from the lever cap is directed over a short space behind the tip thus “reducing to a minimum any tendency to chattering or vibration of the blade or iron in the plane”

The first point is strictly true (it is true you can hone the cutter several times without having to unscrew and reset the cap-iron) but in practice this takes a matter of seconds with a standard cap iron.

The second point does not seem very convincing either, in as far as it relates to an uncommon phenomenon called chatter. This is where the cutter, under pressure from the wood, flexes back and forwards such that it vibrates and makes a tell-tale ridged surface on the workpiece.

We know from Leonard Bailey’s original patents that he had this problem early on when experimenting with thin cutters, but we also know he came up with a subtle change to the cap iron – the addition of a small hump towards the tip of the cap iron - that helped concentrate the pressure of the lever cap closer to the tip of the cutter and resolved the issue under most normal circumstances. This solution can be found in the vast majority of bench planes in circulation (see this post for more about this topic). So Record’s second claim seems to be a questionable benefit.

Having said that, Record do suggest a related but separate benefit namely that the stay-set ‘adds greatly to the rigidity of the plane’, and it is here that the real merit of the design lies.

The intention of Bailey’s modified cap iron was that it would make contact with the cutter at three separate points (the tip, the toe and at near side of the ‘hump’) but the actual implementation in the majority of planes generally don’t achieve this. The standard Record cap iron is no different, making contact only at the tip and around the lever, leaving a fairly large unsupported section in between.

Even with the lever cap installed (top) the cap iron only contacts the blade in two places - the gap is more pronounced with the lever cap removed (bottom)

The fact that millions of planes like this were sold and used over the past 100+ years is a pretty reasonable indication that the standard design is ‘good enough’, but of course that does not mean it can’t be improved upon.

The Record two-part cap iron changes the way the cutter is held to the frog by adding pressure at 3 points, rather than the normal two in a standard bailey plane, thus doing what Bailey had originally intended.

Record Stay-set

Looked at this way the two-part cap-iron can be seen as a natural progression from Bailey’s original idea, albeit a progression that arguably doesn’t really improve performance much in the real world.

So why bother? The reason is a little hard to explain – you really have to try it to find out – but the plane simply feels better with a stay-set cap iron installed. Presumably this is because the stay-set really does add rigidity and our hands are sensitive enough to detect this when using the plane.

Stay-sets in day-to-day use

One of the grumbles about the design is that there can be some play in the connection between the two halves of the cap-iron, and this makes it hard to adjust to a fine setting. For example:

https://popularwoodworking.com/woodworking-blogs/chris-schwarz-blog/tightening-stay-set-chipbreaker

The article above is about the modern Clifton version, and I have to say there was no such problem with my Record examples – the fit is perfect and the bottom half does not move when put in place (note the stern instructions stamped on the Record version to ‘keep groove clean’!). I've no idea if this is a sign of superior engineering at Record or just a matter of luck on my part.

It is very easy to adjust, just like a normal cap-iron: hold the lower half in place with your thumb and tap the screw with a screwdriver until you are in the right spot. It is also convenient to remove the bur after sharpening without having to unscrew and remove the cap-iron.

For completeness I should mention a more prosaic complaint about the design is the tendency for the bottom half to fall off and disappear in the shavings piled under your bench, although I can’t say this is a problem I have been greatly troubled by.

As with any cap-iron, you may find there is a less than perfect fit where it bears on the cutter (which can cause shavings to get caught) and you may have to fettle one or the other, or both, to get a good fit.

Alternatives

Although far from being an essential upgrade, I think the SS cap-iron is a valuable one. It is odd that they were not more popular, particularly since Record offered the SS version of their planes as a standard option and at the same price as the normal version.

Before you rush out and buy one, take a look at the next post which is about Miller Falls’ two part lever cap – an even better idea for improving the rigidity of your plane…

References

| 1⏎ | Traut was a prolific inventor who worked for Stanley – you can read a bit about the tweaks he made to the design after Bailey sold the patent rights to Stanley in the 1860s: Record Bench Planes – a Brief History |